When Outpost started, our leadership team encouraged the engineers to prototype and build/test things fast. In support of that goal, and a company-wide desire to build composites into our structures DNA, I developed the first ever Carbon Fiber CubeSat frames. Two of them are now in Low Earth Orbit.

I had a small budget ($10,000) for this project, which also included the budget for building my composites lab out from scratch in our brand-new facility. I drew on my experience from building composite bicycle frames to create a monocoque, bladder molded, CubeSat frame using “space-grade” materials.

This project challenged my tooling design abilities, composites layup skills, machining accumen, manufacturing know-how, and innovative mindset.

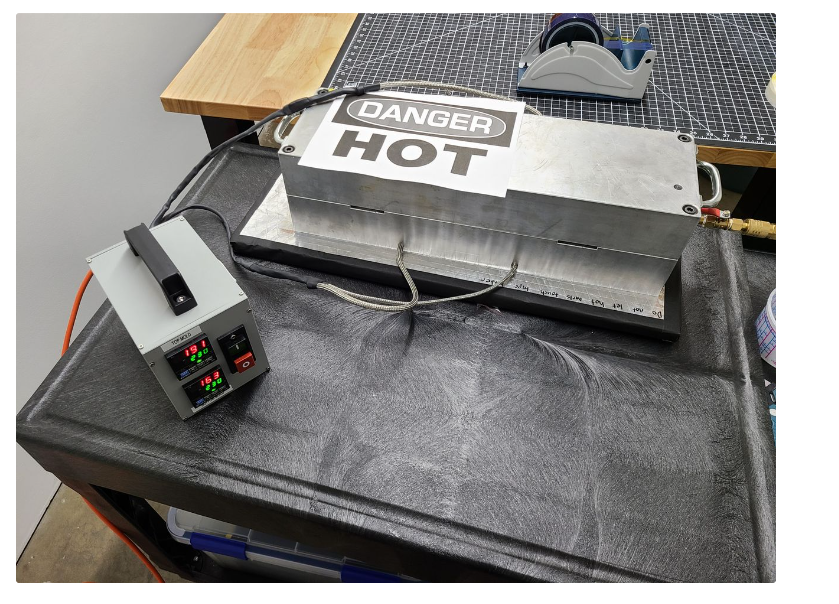

All of the parts you see were made by me, by-hand, using manual machines and curing tools that I designed and built myself in <6 months.

The final parts held to the CubeSat width tolerance of +/- 0.1mm for all rail surfaces and a strict wall-thickness window for internal clearances on electronic parts.